USAGE:

Grooving machine belong to the Gift box package production line equipment. The machine is special designed for notching V type and U type groove, use for industry-cardboard, Ash-cardboard, MDF board and other several of cardboard, to make it suitable for box or other packaging making. Suitable for High quality package, Gift Box, Jewelry boxes, Watch packaging, mobile phone boxes, wine boxes, Storage box, shirt and shoes boxes, make-up, toiletry boxes, biscuits and cakes boxes, note book cover, book shape boxes, hardcover, file folders, display, game boards, display stands, posters and calendars, etc.

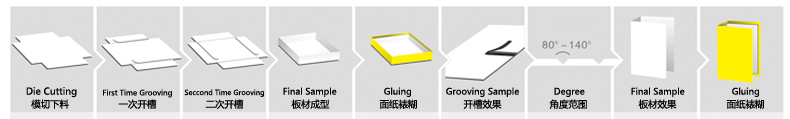

PROCESS:

SPECIFICATION:

Model |

MSKC-1000M |

MSKC-1200M |

MSKC-1300M |

Width of Paper Board |

300-930mm |

300-1130mm |

300-1230mm |

Length of Paper Board |

300-700mm |

300-700mm |

300-700mm |

Min Paper Size |

150*150mm, if smaller size can combine 2/4 on one sheet |

||

Groove Gap (between two grooves) |

2-830mm |

2-1030mm |

2-1130mm |

Thickness of paper Board |

500gsm-3.4mm |

500gsm-3.4mm |

500gsm-3.4mm |

MDF Board |

0.5-3mm |

0.5-3mm |

0.5-3mm |

High Accuracy |

0.1mm |

0.1mm |

0.1mm |

Knife angle |

80-140 degree grooving |

80-140 degree grooving |

80-140 degree grooving |

Knife shape |

V grooving |

V grooving |

V grooving |

Knife material |

Tungsten steel |

Tungsten steel |

Tungsten steel |

Number of Grooves at one time |

9pieces |

9pieces |

10 pieces |

Grooving Speed |

10-35/min(8000-12000unit/8h) |

10-35/min(8000-12000unit/8h) |

10-35/min(8000-12000unit/8h) |

Motor power |

2.2kw |

2.2kw |

2.2kw |

Voltage |

220V/380V/440V 3phase |

220V/380V/440V 3phase |

220V/380V/440V 3phase |

Machine weight |

1100kg |

1300kg |

1500kg |

Gross Weight |

1200kg |

1400kg |

1600kg |

Machine Dimension |

1500*1400*1600mm |

1700*1400*1600mm |

1900*1400*1600mm |

Package Dimension |

1660*1330*1700mm |

1860*1330*1700mm |

2060*1330*1700mm |

MACHINE MAIN BRIEF:

1.After notching, the surface of cardboard is very clean and no dust.

2. The machine is economic, total power is 2.2KW only and it is little noise.

3. The machine can produce about 1000 pcs boxes per hour which feeding by hand, it is fast.

4. The cutting blade can cut 8000-12000 sheets one time, then you should to sharp the blade and it is takes about two minutes only. We will supply a sharpen machine by free and it’s very easy to operation.

5. The machine could groove any thickness from 300gsm-3.4mm.

6. It adopts new way of transportation principle. Wrap the cardboard on the entire surface of the roller (The diameter is 61cm), It can guarantee the groove more accurately, no deviation and straightly.

7. The machine has the features of high accuracy, fast speed and durable cutting blade.

MACHINE DETAILS:

1.Board feeding and after grooving board outing

2.Board grooving through Large roller turns and knife cutting grooves.

3.Different board thickness with different belt pressure, it can adjust by the pressing wheel.

4.V shape and U Shape Grooving Knife depend on customer reminds.

5.Strip Scrap

6.Blade could repeat use, every machine encloses one sharpener.

SAMPLES: