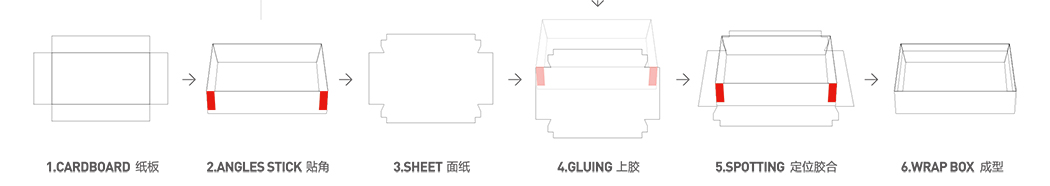

PROCESSING STEP:

USAGE:

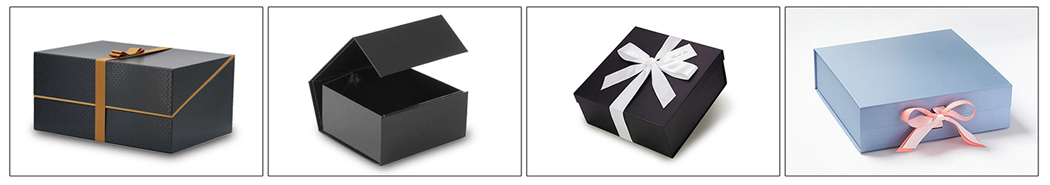

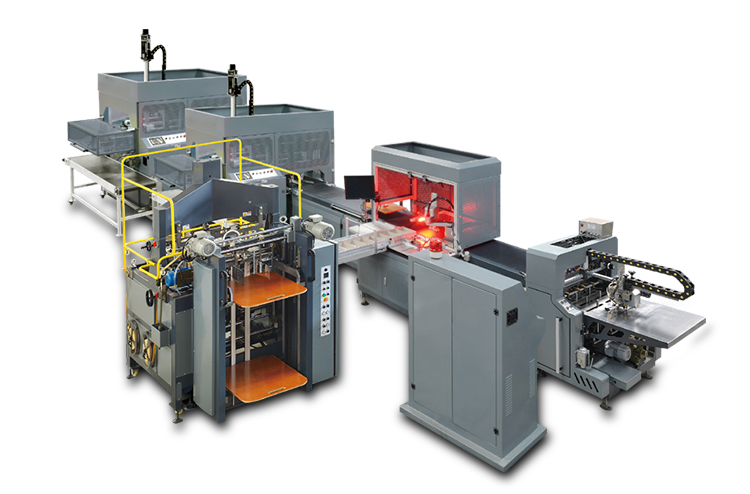

Yamaha series positioning machine-quote the most intelligent and accurate detection method (industrial camera) on the market at present and SCARA is applied to the positioning machine, which not only meets the positioning requirements of most customers in the current market, but also uses the simplest operation method to customers. This product can be used to make all kinds of high-end packaging gift boxes.

This product can be used to make all kinds of high-end packaging gift boxes.

SPECIFICATIONS:

Model |

MS-420Y (Single Forming Station) |

MS-420YS (Double Forming Station) |

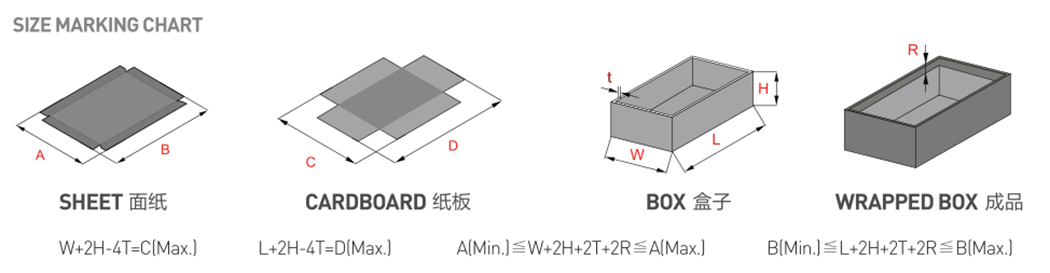

Paper Size(A*B) |

Amin: 95mm Amax610mm Bmin:180mm Bmax:850mm |

|

Paper Thickness |

80-300gsm |

|

Box Size(W*L*H) |

Wmin:60mm Wmax:350mm Lmin:100mm Lmax:450mm Hmin:15mm Hmax:150mm |

|

Cardboard Thickness |

0.8-3mm |

|

Folding Size |

R min:10mm R max:160mm |

|

Folding Ear Size |

10-90mm |

|

Manipulator model |

YK600XG-200 |

|

Position Precision |

≤±0.1mm |

|

Production Speed |

≤18 pcs/min |

≤35 pcs/min |

Cover Paper Stacking Height |

480mm |

|

Cardboard Stacking Height |

1000mm |

|

Air Source Pressure |

0.6-0.8/mpa |

|

Air supply per minute |

180L/min, ensure stable air supply should be equipped with a gas storage tank |

|

Air supply connection |

International quick connector is equipped with a large part, and the air supply pipe cannot be less than 12/mm in diameter |

|

Air source quality |

it should have no water and no debris (customers need to bring their own cold air dryer) |

|

Total Power |

45KW/AC380V |

|

Machine dimension |

7200*4000*3400mm |

9800*4000*3400mm |

MACHINE FEATURES:

1. The newly designed servo-controlled facial paper feeder adopts rear suction to push the paper forward, which effectively prevents double sheets of paper and runs stably

2. The automatic glue viscosity control device can effectively control the viscosity of the glue and ensure the viscosity of the glue and the quality of the finished product

3. The image positioning system cooperates with YAMAHA manipulator to achieve higher speed and more accurate positioning (±0. 1mm)

4. The whole machine is controlled by the operation control system to realize faster debugging and smoother movements of the whole machine

5. The equipment is equipped with the Internet of Things function, which can realize capacity monitoring, remote troubleshooting and system upgrades for customers.

MACHINE DESCRIPTION:

1.GLUING PART--PAPER FEEDING UNIT+GLUE COATING UNIT:

Feeder servo motor control. It can adjust the parameters of each functional position according to the product characteristics to adapt to more product types.

The self-centering function of the paper stack. Motor drive eliminates the error caused by manual adjustment of the paper stopper.

Gluing roller length about 65cm, with copper blade to separate the paper to the rollers.

Hot melt glue system to automatic heating, circulation, mix the glue.

Standard glue viscosity controller to avoid product quality problems caused by glue viscosity and reduce operation difficulty.

2.FORMING PART--CORNER PASTING UNIT:

Automatically non-stop feeding.

The hot-melting paper tape is automatically conveying, cutting and pasting four-corner.

The auto alarm for hot-melting paper tape running out

Corner pasting output conveying with sensor, when box enough position till the sensor, the corner pasting machine stop working, otherwise continue working.

Touch screen panel easy to operate.

3.POSITINOING PART-YAMAHA VISUAL UNIT:

The double-cylinder position ensures each box in a same position, better than box to be positioned by the relative friction between the box and the belt.

Motorized camera adjustment device. It is equipped with roller screws to achieve more precise camera position adjustment, with self-locking function to place the camera moving due to equipment movement.

Japanese YAMAHA manipulator and dual 500W industrial cameras. It with a large field of view, it has better positioning accuracy, and a high-power SCARA achieves faster speed and accuracy.

4.PRESSING PART-SQUARE BOARD UNIT:

Pressing each conveying box to fix the paper and box tightly and remove the bubbles.

High-strength monochromatic PU conveyor belt. It can achieve smaller deformation than rubber and easier to wipe. It can replace the black and white double color belt according to customer needs.

5.BOX FORMING PART-BOX WRAPPING UNIT:

Lift the box and cover paper by 15mm via the air cylinder which is efficiently avoiding the scratches of the paper.

Blocking alarm device, automatic detect the discharge and feed to avoid damage once blockage.

Cover paper pasting, folding and press in one step. It with pressure bubble structure, the finished product no need the bubble pressing machine.

6.PLC PART:

Main components in stable famous international brands.

Electronic cam servo control system, to achieve more coordinated action shaping and one-key speed-up.

SAMPLES: