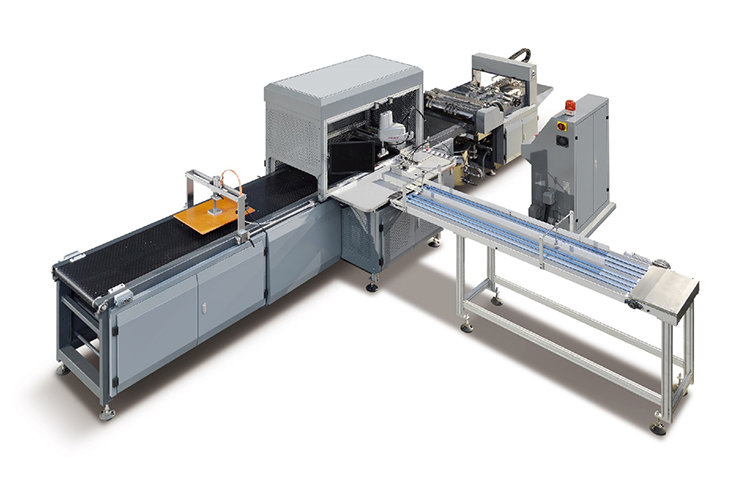

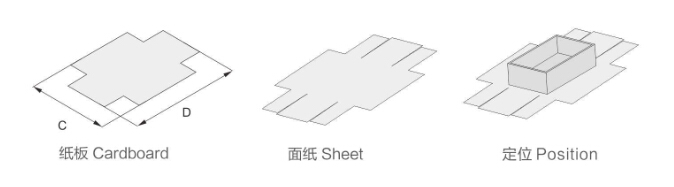

PROCESSING STEP:

USAGE:

The machine is mainly used for producing boutique boxes with high requirements, like high grade boxes for iPhone, iPad, jewelry gift, makeup, etc.

It can work with rigid box forming machine and automatic corner pasting machine according to requirement of the boxes

SPECIFICATIONS:

Model |

SJ-460Y |

SJ-600Y |

Paper Wrap Size (A*B) |

Amin 100mm Amax 460mm Bmin 190mm BMax 830mm |

Amin 100mm Amax 600mm Bmin 190mm BMax 1030mm |

Paper wrap thickness |

100-200gsm |

|

Finished box size(L*W*H) |

L min 100mm L max 320mm W min 50mm W max 240mm H min 15mm H max 125mm |

L min 100mm L max 420mm W min 50mm W max 320mm H min 15mm H max 150mm |

Position precision |

±0.1mm |

|

Production speed |

≤30 sheets/min |

|

Motor power |

6.65kw |

|

Heater power |

6kw |

|

Machine weight |

1300kg |

1500kg |

Machine dimension |

L7200*W3500*H2100mm |

L7200*W3500*H2100mm |

MACHINE FEATURES:

1. Adopts paper feeding principle same with automatic rigid box maker, with stable performance

2. Adopts YAMAHA robot, can automatically fetch the rough box to the required position accurately

3. Adopts visual positioning system, the positioning accuracy is s+0.1mm

MACHINE DETAILS:

FEEDER PART:

Feeder delivers paper automatically, it draws single sheet exactly each time, keep them still during conveyance.

GLUING PART:

Hot melt glue system can do automatic heating, circulation, stirring and accurately control the needed viscosity of the glue. Automatic gluing roller washing after gluing work is done.

CONTROL PANEL:

Convenient control panel that equipped with advanced touch screen. Human machine interface can switch the language freely between Chinese and English so that the operation is much easier.

POSITION PART:

adopt two imported 5 million pixels industrial camera, and YAMAHA robot positioning, accuracy + / - 0.1 mm

PRESSING PART:

Square pressing mold press the box that enters its pressing range. The pressing work will expel air bubbles between the cardboard and cover paper, making box surface even and smooth.