USAGE:

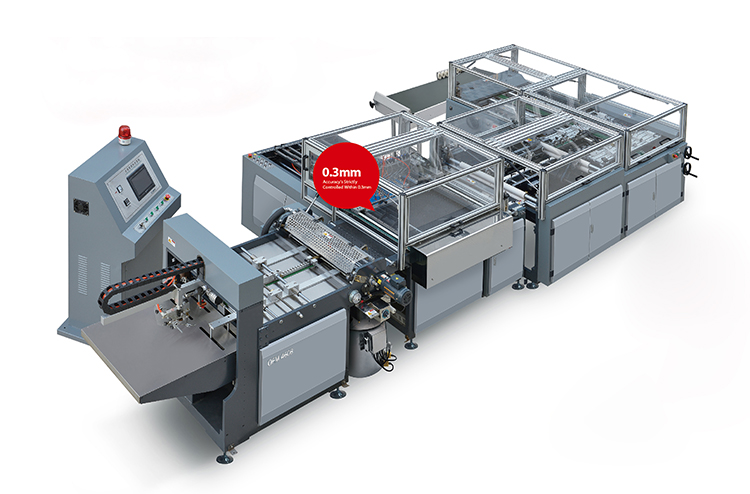

It can be used for efficiently producing various of high-quality hardcover book case, book bind folder, game board, books, table calendars, diaries, photo albums and high-end gift packaging (cigarette, wine, higher phone box, tea table, moon-cake boxes, home visits, large gift boxes, etc.) Excellent quality, ranges size, high speed, suitable for ranges of products, stable and reliable operation, easy operation and maintenance, saving labor and energy.

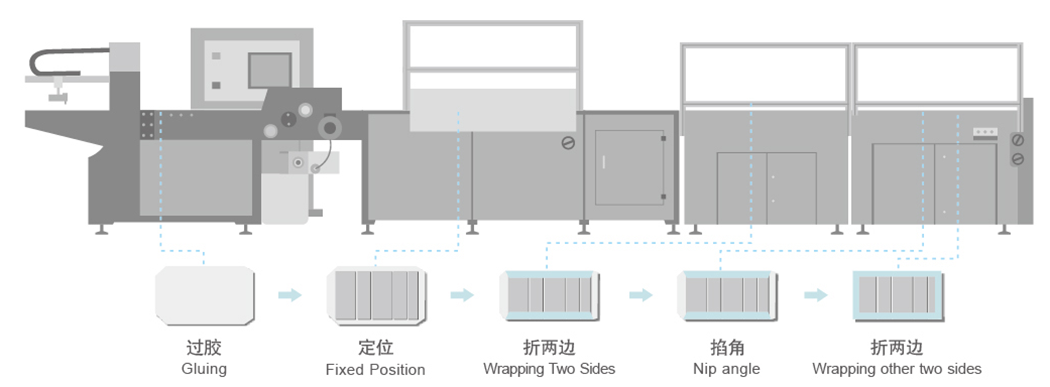

PROCESSING LINE:

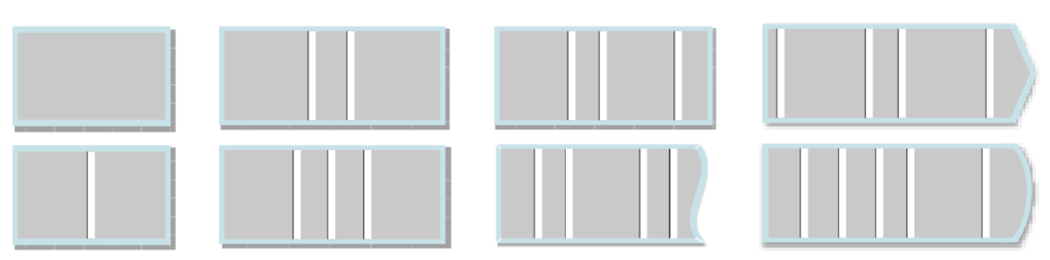

PRODUCT DRAWING:

SPECIFICATION:

Model |

QFM-460B |

QFM-600B |

Length of paper |

190-830mm |

190-1030MM |

Width of paper |

100-460mm |

100-600MM |

Thickness of paper |

80-200gsm |

80-200gsm |

Thickness of cardboard |

1-3mm |

1-3mm |

Min width of spine |

8mm |

8mm |

Long side position precision |

≤±0.25mm |

≤±0.25mm |

Working Speed |

0-35pcs/min. |

0-35pcs/min. |

Power supply |

12kw |

13kw |

Dimension |

L7800XW2100XH1550mm |

L8900XW2250XH1550mm |

Weight |

3500kg |

4500kg |

MACHINE FEATURES:

1.Transmission of paper adopts automatic paper transmission feeder with mutually combined with vacuum suction separated paper and computer controlled vacuum blower wheel paper delivery.

2.Paper enters band steel ball roller conveyors new guiding rail for positioning, and then automatically coat glue for re-adoption of optical fiber precise tracking error correction device.

3.It adopts unique development philosophy to solve problems including getting dirty and scratching. Through belt-oriented chaff transmission system developed by unique professional technique, sucker manipulator transmits product onto vacuum air-transmission conveyor belt for transmission which can avoid phenomenon including surface occurring getting dirty and scratching to meet requirements for high-quality products.

DETAIL IMAGES:

FEEDER:

Stable and Accurate Institution Providing Automatic Feeder Paper Delivery's (Patent No.: 2L201120141210.4) For implementation of this patent, utility model's structure is simple and compact, debugging is simple and convenient, and paper feeding is stable and accurate, it may not cause deformation of paper and simultaneously paper feeding is quick and production efficiency is high

GLUING PARTS:

Line-touch Designed Copper Scraper

The copper scraper cooperates with the glue roller by line-touch design which makes the scraper more durable.

Ultrasonic Double Paper Detector

Pre-rectifying paper platform is equipped with ultrasonic double paper detector.

NON-STOP BOTTOM-DRAWN CARDBOARD FEEDING DEVICE

Adopt per-stacking non-stop bottom-drawn Cardboard Feeding device, which improves the production speed.

FOLDING PARTS:

This technology has solved phenomenon including soiled and scratched surface causing process of production of chaff and it meets requirements for high-quality finished products ( Patent No : 2L201020118418.X ) . Implementation of this patent adopts cardboard transmission mechanism to transmit lateral nip angle mechanism and lateral binding mechanism from vertical binding mechanism to enable it not to scratch it surface by mechanical parts during nip angle operation and enable surface for facial tissue to keep smooth and bright and clean