USAGE AND FUNCTION

The paper cutting machine has features as automation paper cut and paper send, high cut precision low noise and long life usage. lts design structure is easy to operate and insure safety. lts paper sending system adopts whole slot-less chrome worktable, linear guide and high-speed ball screw which insure the correct position with high speed. Both of the paper clamping device and paper cutting device adopts hydraulic pressure. The pressure is adjusted step-less. The big pressure adjusting range insure various paper cutting pressure needs. It is equipped with photo cell cutting, button with double hands, knife light line knife seat electric devices, mechanical safety devices of built-in electronic knife lock for cutter cycle. Therefore it can insure the operator’s safety and convenient operation. This series of machine is suitable for cut carbonless paper, art paper, gray paperboard, etc. Especially for the workshop school advertisement agent and company etc. The hydraulic system reaches the European safety standard and the series of machine has passed CE certificate.

PRODUCT DESCRIPTION

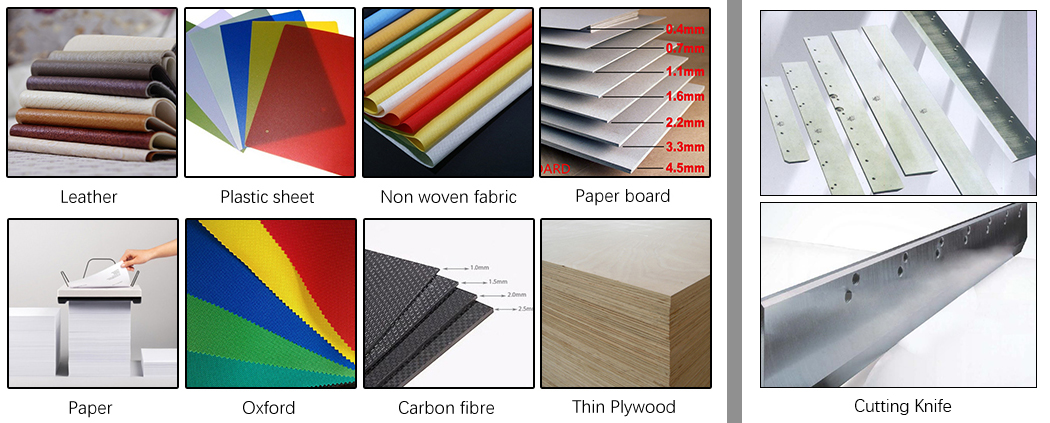

1.USAGE: Program Control Paper Cutting Machine is used to cut the printing paper of various kinds, paper products, plastic, thin film, leather, slice of non-ferrous metal, etc.

2.COMPUTER: it adopts 7 inch color liquid crystal display screen,500 groups programming capacity, each of them can store 999 cuttings' datum of different locations;0.05 mm position accuracy; six kinds of language; the working speed is 6-18m/min.

3.DOUBLE HYDRAULIC DEVICE: the hydraulic system adopts the Germany advanced technology. Equipped with combined hydraulic valve, double hydraulic controlling structure, it approves hydraulic device greatly. The hydraulic device pass CE certificate.

4.DOUBLE GUIDE DEVICE: the paper pusher adopts double imported linear guide and roller ball screw, which can prolong the machine use life, and can bear the high speed paper delivering.

5.PHOTO CELL: it is equipped with a photo cell safety protection device.

6.OVER LOAD PROTECTION DEVICE; convenient knife changing device.

7.WORKTABLE CHROME TREATMENT: the worktable and side board surface are all adopted chrome treatment to improve the precision and quality of the machine.

8.AIR BALL: air balls are installed in the worktable. The paper sending work will be easy and accurate.

9.CUTTING CONTROLLER: both of the user’s hands operate the machine. It can cut paper in one time.

10.ELECTRONIC KNIFE LOCK: when the machine is malfunction, the electronic knife lock will lock the knife, and the machine will stop cutting to protect safety.

11.SAFETY NOTICE & GLASS COVERS: the machine has passed CE certificate. All the safety notice and direction mark is used to cause the safety attention of the user, and do protection and maintenance in time.(optional)

12.MAIN ELECTRIC DEVICE ARE IMPORTED FROM GERMANY, FRENCH, JAPAN, ETC.

680 SERIES TECHNICAL DATA

Model |

Unit |

680 |

Total width of machine |

cm |

106 |

Half width of machine |

cm |

53 |

Total width of machine |

cm |

106 |

Total length of machine |

cm |

152 |

The length from cutting position to the front table |

cm |

50 |

the height from working table to ground |

cm |

90 |

Total height of machine |

cm |

143 |

Max. cutting length |

cm |

68 |

The length from cutting position to back table |

cm |

102 |

The width of working table |

cm |

68 |

Max cutting width |

cm/lnch |

68 |

Max. cutting length |

cm/lnch |

68 |

Max cutting height |

cm/lnch |

8 |

Main motor power |

KW |

2.2 |

Weight |

KG |

800 |

Width of machine with sideway |

cm |

106 |

Width of machine without sideway |

cm |

|

Machine Length |

cm |

152 |

Machine Height |

cm |

143 |

Front table length |

cm |

50 |

Table Height |

cm |

90 |

Min Clamp pressure |

N |

100 |

Max Clamp Pressure |

N |

80000 |

Knife thickness |

cm |

78×10×1 |

Grinding reserve |

cm |

2.5 |

Min cut without false clamp |

cm/lnch |

2.5 |

Min cut with false clamp |

cm/lnch |

|

Cutting speed |

cycles\min |

20 |

Packing size (L×W×H) |

cm |

175×122×178 |

Voltage(three-phase) |

V |

220 |

Wire size |

mm2 |

4 |