USAGE:

Grooving machine belongs to the gift box package production line equipment. The machine is special designed for notching V type groove, use for industry-cardboard, Ash-cardboard, MDF board and other several of cardboard, to make it suitable for box or other packaging products.

The machine composed of two grooving part and conveyor belts connected together. Its crosswise and lengthwise V grooving at once with high efficient. It adopts new way of transportation principle, wrap the cardboard on the entire surface of the roller(The diameter is 60cm), which can guarantee the groove more accurately, straightly and no deviation. The machine has the features of high accuracy, fast speed and durable cutting blade.

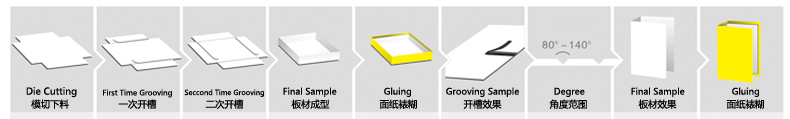

PROCESS:

SPECIFICATION:

Model |

MSKC-1000 |

Width of Paper Board |

130-700mm |

Length of Paper Board |

130-700mm |

Groove Gap (between two grooves) |

2-660mm |

Thickness of paper Board |

300gsm-3.4mm |

Knife angle |

80-140° Adjustable |

Knife material |

Tungsten steel |

Knife shape |

V shape grooving |

Total grooving knife at once |

5 pieces |

Grooving Speed |

30-40pcs/min |

Power |

2.2KW/380V |

Machine weight |

3500kg |

Machine Dimension |

4300x2300x1500mm |

MACHINE FEATURE:

1. Automatic feeding, original correction device,rectifying zero clearance smooth transition,easy to operate.

2. Double correct device, it can adjust according to the paper thickness and size.

3. Easy to adjust the grooving degrees and V groove effect smooth, with no dust.

4. The wasted corners and the finished product are transported to the corresponding station of each other.

MACHINE DETAILS:

1.Machine is controlled by a PLC programmable controller(separated computer cabinet) for synchronization and coordination. It with 10-inch WEINVIEW touch screen for easy operate.

2.Automatic feeding part(automatic paper feeding speed 80-120 meters per minute). Cardboard carry by the convey belt, double sides position plate are adjustable, they can ensure the precision.

3.The correction device. It will correct the direction of the cardboard and make it precision.

Correction by the plate support and auxiliary aluminum strip.

4.Cardboard grooving, belt transported to keep the cardboard on the large roller surface and knife make grooves. Easy to adjust the degree and adjust range is 80-140 degrees.

5.Second grooving correction device, and transport the cardboard via belt from bottom to up. After second grooving the brush auxiliary to remove corners.

6.The whole transmission system has controlled by gear, chain and timing belt transmission, which extends the service life of the whole equipment and improves the quality of the equipment.

7.The imported alloy blade can be repeatedly sharpen and reused.Each machine is equipped with a sharpener. It will take only 2-5 minutes to sharpen the knife.

SAMPLES: