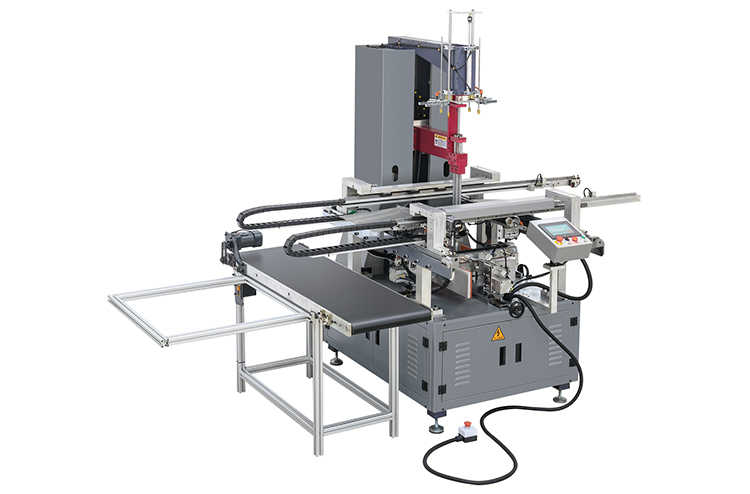

USAGE:

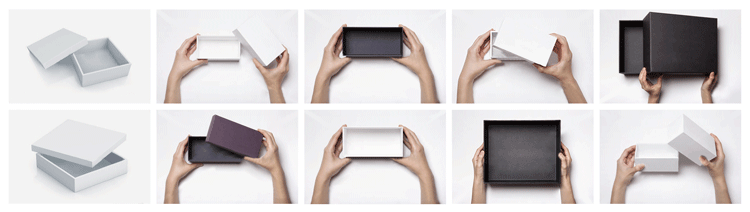

MS-480AM servo automatic rigid paper box forming machine is the ideal processing equipment rigid box, box. First, Inner box bottom paste with surface paper, then fix the product on the mold of the forming machine by hand, different size box with different mod, then automatic four side pasting, folding, and bubble pressing. Hardcover box can greatly improve the production efficiency.

SPECIFICATION:

Model |

MS-480AM |

Max box size |

480*400*150mm |

Min box size |

60*100*15mm |

Speed |

15-20pcs/min |

Voltage |

220V 50HZ |

Air pressure |

0.8mpa |

Weight |

950kg |

Dimension |

1300*1900*2300mm |

Package dimension |

1600*2100*2400mm |

FEATURES:

Machine with servo pneumatic, PLC control.

Machine is debugged by man-machine interface is simple and easy to adjust the selection.

Machine all control parts adopt international high-end brands, low failure, high precision.

Machine with touch the emergency stop switch, such as an emergency press automatic stop.

FORMING PARTS:

This parts can achieve several actions, pasting the four side sheet, folding corner, front and hind folding, pressing, left and right folding, pressing and then separated box output.

Each actions finished by the cylinder and also can setting the action lasting time, which are quick and high precision.

1.PASTING.

Four round brush insure pasting cover papers on the square box four sides, especially some box deep folding or with high height.

2.FOLDING CORNER.

The step can ensure the box with straight and beautiful angles. Its mode can be setting to once or twice.Once model is four corner folding executed at the same time, twice model will execute front and hind corners separately.

3.SIDES FOLDING AND PRESSING.

The step folding the four sides, first is front and hind sides, second is left and right sides. Pressing can remove the box surface bubble insure box with flat surface.

Pressing board with imported materials which can be countless times press