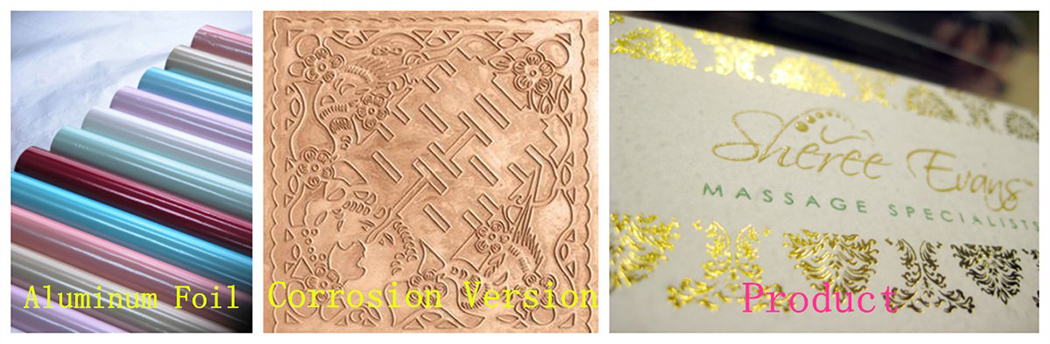

The working principle of hot stamping machine:

At a certain temperature and pressure, The aluminum foil transfer to the product surface, different patterns and words with different Zinc or Copper corrosion version.

ALUMINUM FOIL+CORROSION VERSION+MACHINE=PRODUCT

USAGE:

Hot foil stamping machine belongs to printing and packaging equipment.

They are used for hot stamping all kinds of colored aluminum foil and embossing or die cutting different kinds of pictures, clothing ticketing, greeting cards, trade mark, books cover, note book, packaging cartons, paper boxes, paper bags, Cork pad, folders, and other high grade decoration and printing materials, etc. The suitable product materials are including paper, cardboard, plastic (PVC,PP,PE), leather, wood and cork, etc, So that they are necessary equipment for printing factory, packaging Enterprise and Office stationery manufacturer.

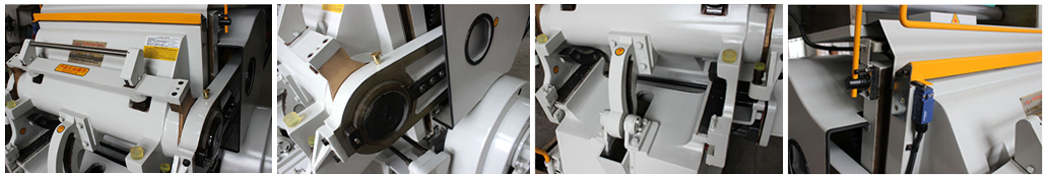

Machine Brief:

1.High strength due to one piece casting by using top-ranking material for machine body.

2. Single plate electromagnetic clutch is sensitive and reliable.

3. Operation position is reasonably arranged, moving-bed can be opened to its optimum

4. Computer controlled is stable

5. Skipping distance controlled by stepper motor is accurate, so as to save foils.

6. Hot stamping parts are controlled by computer system through setting data by handler, easy to operate. Feeding paper and get out by hand.

7. With three functions of continuous creasing and cutting, opening well operation and closing dwell operation and a large dwell adjusting range.

8.Stainless steel cutting plate.

9.Automatic oil pump (electric)

The above machines parts are same

TYMB750: 2 groups temperature control TYMB930/1040: 3groups temperature control

Collection speed adjustment Electric automatic oil pump Manual central lubrication device

Normal standard:

Stainless steel plate; Copper sleeve; manual oil pump

CE standard:

CE safe guard; Infrared ray device; Schneider or Siemens electric; Electric automatic oil pump;

Optional: NTN/NSK bearing; ABB motor;

Specification:

Model |

TYMB750 |

TYMB930 |

TYMB1040 |

Max. area available |

750×520mm |

930×670mm |

1040×720mm |

Max. Stamping area |

665×460mm |

920×665mm |

1020×700mm |

Skip range |

1-500mm |

1-665mm |

1-700mm |

Foil-delivered length |

1-500mm |

1-665mm |

1-700mm |

Foil-feeding precision |

1mm |

1mm |

1mm |

Foil-delivered group |

2groups |

3group |

3groups |

Skip frequency |

1-99times |

1-99times |

1-99times |

Working speed |

25±2times/min |

22±2times/min |

21±2times/min |

Working pressure |

150T |

170T |

190T |

Temperature range |

1-170℃ |

1-170℃ |

1-170℃ |

Electric power |

7kw |

12kw |

12kw |

Main motor power |

2.2kw-6H 380V |

4kw-4H 380V |

4kw-4H 380V |

Net weight |

1800kg |

3500kg |

3800kg |

Gross weight |

2000kg |

3700kg |

4000kg |

Dimension(L*W*H)mm |

1900×1450×1950 |

1800×1900×2150 |

2100×2100×2300 |

Package |

Wooden case with free fumigation |

||

Color |

Customize for customer |

||

Voltage |

Customizable |

||

Sample:

Package: