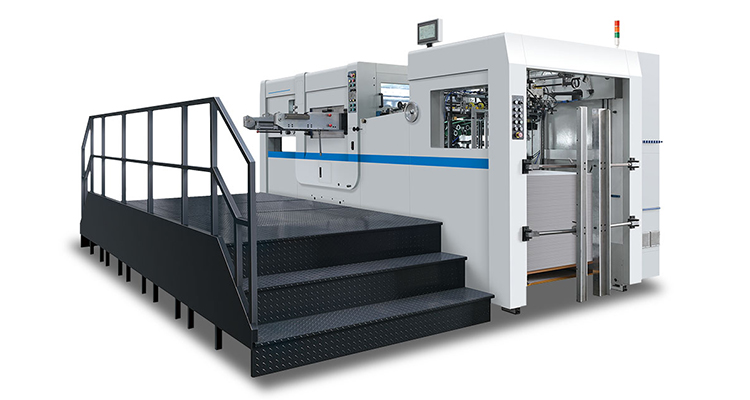

FEATURES

★ Complete design, accurate installation, high stability, high security, low noise.

★ Adopt worm, worm gear, crankshaft transmission, high cutting pressure, high durability.

★ High precision intermittent mechanism, high cutting precision, running steadily.

★ Adopt European technology feeder, suction adjustable, steadily, precise, good paper applicability.

★ Non-stop feeding, pre-stacking and delivery device can shorten the auxiliary time, improve the efficiency.

★ Automatic pressure adjust system, pressure digital display.

★ Human-friendly designed die frame and baseplate, makes installation, adjustment convenient.

★ Pneumatic die locking device, die frame fixed more steadily, accurately, time saving.

★ Front lay, side lay, feeding device fine tuning device, paper positioning more accurate。

★ Double, crooked, empty optoelectronic position control, ensure the paper in the right position, reduce waste.

★ Electronic control module design, adopt imported electronic components, ensure the accuracy and reliability.

★ Touch screen man-machine interface, real-time monitor the running situation, makes machine adjustment, trouble shooting more convenient.

★ Cycling cooling oil supply system ensure the movement parts get adequately lubricated to ensure the durability.

★ Adopt fixed quantity at fixed timing oil supply system, ensure the movement parts get adequately lubricated to let better durability.

Max Paper Size |

1050x750mm |

|

Min Paper Size |

400x370mm |

|

Max Cutting Size |

1040x730mm |

|

Cutting Precision |

≤±0.1mm |

|

Max Cutting Pressure |

320N/cm2 |

|

Max Cutting Speed |

7500s/h |

|

Pre-Stacking Height |

1550mm |

|

Delivery Stack Height |

1400mm |

|

Application |

White Board |

0.1-2mm |

|

Corrugated Paper |

<4mm |

Main Motor Power |

11kw |

|

Total Power |

17.8kw |

|

Dimension |

4850(+1650)x2100(+1600)x2350mm |

|

Weight |

15500kg |

|