USAGE:

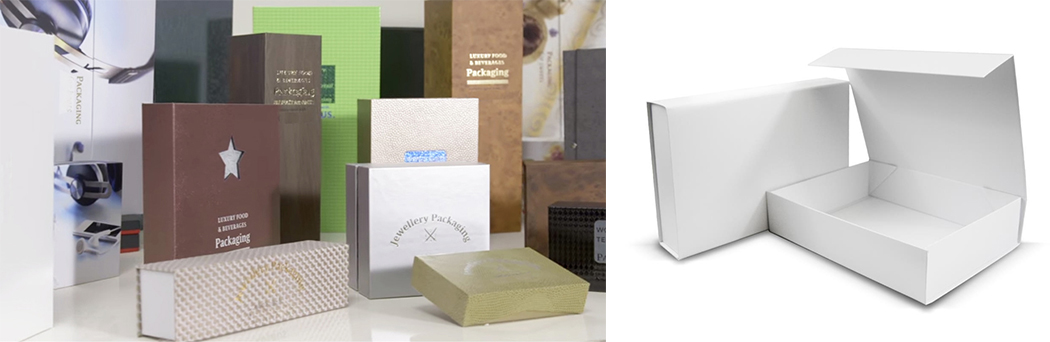

MSFB-1000 semi-automatic book-like box assembling machine is the necessary processing equipment for the medium and large enterprise which producing hardcover box, Luxury packaging manufactured.

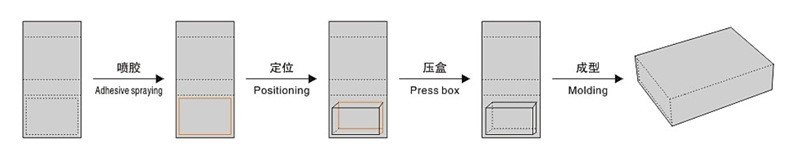

It is automatic position fixing and glue spraying by manipulator. It applies hot melt adhesive and double stations to fulfill the functions of automatic local coating, positioning and box pressing, ensures precision, strong adhesion, no missing and high efficiency during the processing of box fix together.

SPECIFICATION:

Size of Box |

30x30mm~1000x700mm |

Speed |

2200~3000PS/H |

Glue line thickness |

1-6mm |

Glue quantity |

1g-5g/s |

Hot glue temperature |

180° |

Air Pressure |

5-8kg/m2 |

Power |

4.5KW |

Dimension |

3700x1400x1900m |

Weight |

1000kg |

Gross weight |

1200kg |

FUNCTION:

1.The glue spraying system applies 32-bit processor and Software optimization calculation, to achieve high precision automation.

2.Digital Interface, 5.7” touch screen easy control.

3.We could receive special customization depend on customer reminds.

MACHINE DETAILS:

MANUAL FEEDING PARTS:

It with two working stations, positioning frame can be easy adjust via the screw. Hardcover keep still on the conveyor belt, which can protect the hardcover surface.

GLUING SPRAYING PARTS:

Glue spraying moving trail controlled by servo motor, two guns spraying pattern can be set via the touch screen according to product various shapes.

Glue thickness also can be adjustable.

PRESSING PARTS:

The parts controls by cylinder, to make the inner box stick more stronger with hardcover

GLUING MACHINE PARTS:

Standard gluing machine uses for the hot melt glue(Pressure sensitive adhesive), it is environment-friendly, machine place on the machine top.

Cold glue is optional, if product needs the cold glue, it can be customized, cold glue tank attached below right.

SAMPLES: