USAGE:

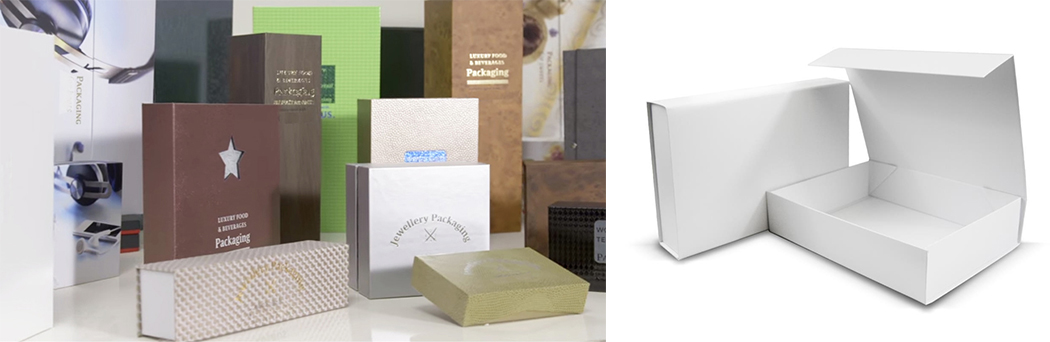

Automatic book box assembly machine is the necessary processing equipment for the medium and large enterprise which producing hardcover box, wine box, gift box, luxury packaging box.

SPECIFICATION:

Hardcover Max size |

145*220mm |

Hardcover Min size |

500*900mm |

Hardcover thickness |

1-4mm |

Accuracy |

±0.2mm |

Glue line thickness |

1.5-4mm |

Glue quantity |

1g-5g/s |

Glue temperature |

180 ° |

Work speed |

25 pcs/min |

Total power |

6kw |

Air Pressure |

5-8kg/m2 |

Dimension |

4600*1600*1900mm |

Package dimension |

3050*1920*1760mm/2170*1370*1460mm |

Net weight |

1000kg |

Gross weight |

1200kg |

Package |

Free fumigation wooden case |

*Accept customize model according customers requirements

MACHINE FEATURES:

1.The machine pays attention to the safety, useful, and good appearance.

2.One-line display and removable operating panel with less footprint, one worker can put the hardcover and inner box, reduce labor cost.

3.Under suction design and the hardcover keeps still on the belt avoid any scratches.

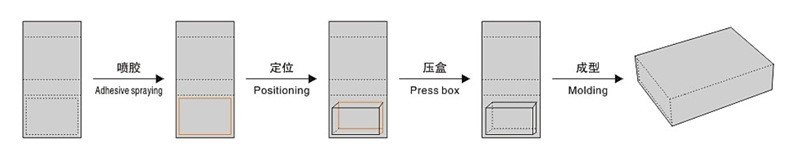

4.Spray glue trail could be intelligent edit according to different kinds of design hardcover box.

5.0.4mm gluing nozzles ensure the economic and reasonable amount glue

6.Machine with 5 servo motors ensure the moving trail precision.

7.Two ways of picking up inner box, suction(common) and clip(optional).

8.Two glue application, hot melt glue and cold glue. Cold gluing system(optional)

9.Achieve pressing and folding function at one step designed by our own R & D department.

MACHINE DETAILS:

HARDCOVER FEEDING PARTS:

Seven pairs suction nozzles ensure vacuum under suction, and suction design can avoid damage and scratches to the hardcover surface.

GLUING SPRAYING PARTS:

The gluing pattern can be settled any patterns according to the different kinds of products.

Two servo motors control the movement of glue gun. X-axis and Y-axis each controlled by one servo motor.

Gluing gun nozzles is 0.4mm, glue line thickness is adjustable, 1.5-4mm.

Hot melt gluing machine has a capacity of 5L, it with stable pressure and temperature. Its temperature range is 0℃--400℃, recommended temperature about 175 ℃

Glue choice: Cold glue system(optional)

PAS702 PRESSURE-SENSITIVE ADHESIVE/HOT MELT GLUE/WHITE GLUE

INNER BOX PICKING UP PARTS:

Air valve control airflow, accurate and thorough, every action step in place.

It can be non stop feeding, and easy to operate, put the box at the beginning, the box will move by belt and keep in line.

The part can connect with box forming machine, it can save labor and the box storage space.

Two servo motors control the movement of box positioning. X-axis and Y-axis each controlled by one servo motor.

INNER BOX POSITIONING PARTS:

Cylinder positioning the hardcover and servo control the movement of the box ensure its precision.

BOX PRESSING AND FOLDING PARTS:

Pressing needs to make mould according to the box, folding unit can one side or both sides fold

SAMPLES: