PRODUCT DESCRIPTION:

The MS-800 fully automatic collapsible rigid box making machine is independently developed by our company, the world's first, has a number of patents, integrating the advantages of the most advanced technology at home and abroad, uses a unique squeegee process, and visual positioning. This machine uses hot melt glue and partial scraping glue, strong adhesion, fast speed, One-off folding box, overall overturning the traditional packaging efficiency slow, the disadvantages of large space, optimized storage space, and environmental protection characteristics, etc. And so on, is the ideal equipment for gift box production.

FINISHED PRODUCT DISPLAY:

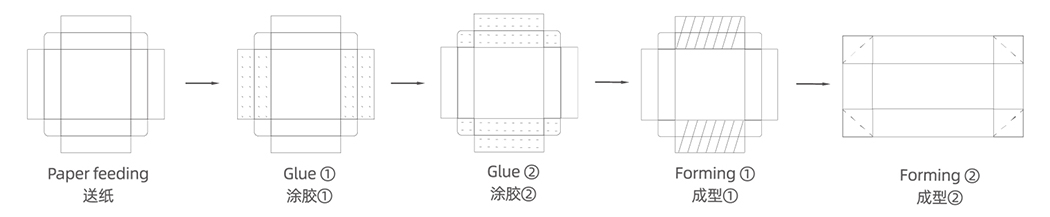

PROCESS STEP:

MAIN TECHNICAL PARAMETERS:

Model |

MS-800 |

Max Paper Sheet Size |

800*800mm |

Min Paper Sheet Size |

220*220mm |

Paper Thickness |

250-300gsm |

Paper Pile Height |

380mm |

Speed |

22pcs/min |

Air Pump Requirement |

15L/min 0.6mpa |

Electric Heating Power |

4kw |

Motor Power |

9.5kw |

Weight |

2600kg |

Dimension |

8500*4100*1900(L*W*H) |

The relationship between the size of the box and the paper after forming: L+4h≤800 W+4h≤800 L+4h≥220 W+4h≥220 |

|

PRODUCT ADVANTAGES:

1.A folding box made of a white cardboard folded with pre-set indentation lines, and is characterized in that the polygonal white cardboard extends to the front and rear, left and right sides respectively, and pastes at least 2 or 4 A piece of gram-weight cardboard, a new type of folding carton that is formed at one time.

2.The technical content of the folding box of the present utility model relates to the use of multiple reinforcing sheets to reinforce the strength of the front and rear walls and the multiple side walls so that the folding box can maintain the structure while reducing the area required for cardboard preparation under consideration of environmental protection. Structural stability can still be maintained

3.The new folding box not only protects the product, greatly reduces transportation costs and storage space, but also brings out the texture of the product, so that the overall presentation is exquisite visual effect, without losing the advantages of a stable structure.

4.The gluing method of this structure is completely different from the traditional paper boxes. Most traditional paper boxes use large-area paper gluing. The paper is prone to mold and deterioration, and its surface is deformed and bent, which seriously affects the structure and environmental protection requirements. However,this new type of folding box uses a small amount of glue or scraping glue to complete the paper gluing, using international environmentally friendly hot melt glue, which not only ensures the reliability of the structure, but also perfectly solves the green theme

MACHINE DETAILS:

FEEDER PART

Back push feeding method can avoid multi sheets feeding, feed stably.

GLUING PART

The most advanced high-speed local squeegee technology replaces the traditional glue spray line method, which makes the glue on the surface of the paper more consistent

The wear-free closing design of the needle valve can accurately cut off the glue flow

This machine uses high temperature hot melt glue to ensure the efficiency and quality of the box

CONTROL PART

It adopts the most advanced68-bit processor and optimized software algorithm of the German BECKHOFF system to achieve high-precision automation performance

Humanized digital interface , equipped with 21-inch touch screen , easy to use

POSITION PART

It under feeding method can fill material in time and easy to operate.

It can feed at least 2 or 4 pieces of gram-weight cardboard, two type box can achieve in one machine.

FOLDING PART

Folding and pressing the inner collapsible box, finished product can transport to the automatic assembling machine, assemble with the hardcover.