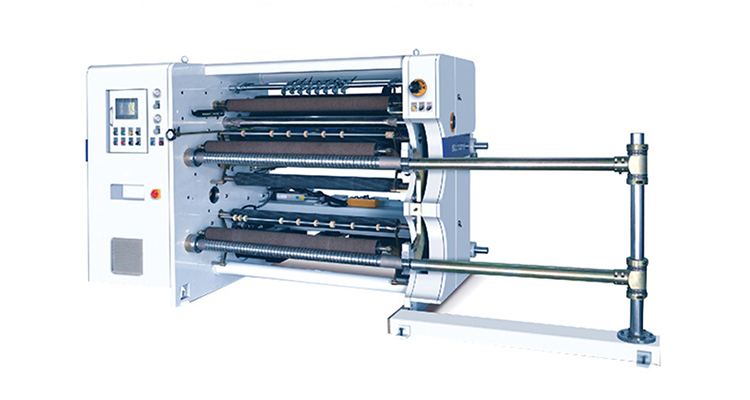

The MSZSFQ series machine suitable for jumbo roll material slitting, such as cardboard paper, craft paper, Self-adhesive paper,insulation paper, self adhesive sticker paper, paper label, plastic label, coated paper, PVC, PET, BOPP, PE etc plastic film.

FEATURES

1. The machine use PLC control,three pcs Servo Motors, tension automatic control surface¢er rewinding together way(The rewinding way make the narrow roll hard and slitting surface smooth.)

2. The machine use frequency converter to adjust and control speed,it can keep stability when the speed running up.

3.Automatic counter meter, auto alarm and auto stop when the machine had fault. Automatic stop when reach the rewinding roll size you are setting.

4.The rewinding use A、B two pcs pneumatic slip shaft structure, unloader operation easy.

5.The unwinding Web Guide(EPC) use ultrasonic control way to keep and correct the web material position.

6.It use round blade slitting knife , the waste material automatic take out by blower fan.

7.Auto pneumatic shaft-less loading structure.

| Material Feeding Width | 1300mm/1600mm |

| Max Diameter of Unwinding | 800mm/1400mm |

| Max Mother Roll Weight | 600KG |

| Min Width Finished Roll | 30mm |

| Max Diameter Finished Roll | 600mm |

| Material | PVC,PET,BOPP ,PE etc plastic film |

| Precision | ±0.2mm |

| Slitting Capability | 20-200um plastic film or 30-300gsm paper |

| Slitting Speed | 300m/min |

| Total Power | 21kw |

| Main Motor | 5.5kw,Servo motor |

| Rewinding Motor | 5.5kw,Servo motor(2sets) |

| Frequency Converter | SINEE(3sets) |

| Transmit Way | Synchronous |

| Feeding Roller | Rubber roller |

| Transmit Roller | Aluminum roller |

| Rewinding Way | Center rewinding type |

| Power Input | 380V,50HZ,3PH |

| Machine Size | 4000*2000*1760mm |

| Machine Weight | 3500kg |