USAGE:

Grooving machine belongs to the box package production line equipment. The machine is special designed for paper card and greyboard V type grooving. It suits for box, case or other packaging product, such as phone box, medicine box, watch box etc.

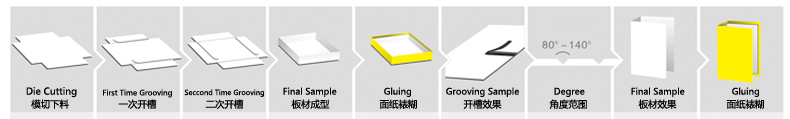

PROCESS:

SPECIFICATION:

Model |

MSKC-930KZ |

Min Sheet Size |

100x100mm |

Max Sheet Size |

550x930mm |

Thickness |

250gsm-2mm |

Knife Angle |

80-140° adjustable |

Feeding Correction Length |

820mm |

Total Grooving Knives Number |

12 sets, each host with 4 set grooving knives, and 3 row knife holder |

Knife Material |

tungsten steel |

Grooving Speed |

20-32m/min(considering300*300mm 130-150pcs/min) |

Roll Diameter*Length |

600x100mm |

Power |

2.2 kw |

Voltage |

380v 50hz 3phase |

Precision |

±0.1-0.2 mm |

Net Weight |

1500kgs |

Package Dimension |

2550x1650x1750mm |

Gross Weight |

1850kgs |

MACHINE FEATURE:

1.Double station, can do horizontal and vertical grooving on both sides at the same time

2.Can be used for both cardboard and grey board products

3.The machine is equipped with a finished product collection tank, which is convenient for operators to sort out

MACHINE DETAILS:

1.Belt feeding structure suit for the paper card and grey board material

2.Adjustable size to suit large and small sizes, work for the box or hardcover case

3.Single-sided pressure wheel correction is more accurate.

4.The counting photoelectric can count the output.

5.The part with 3 rows of knives, each row has 4 knives, which can meet the needs of multiple products to open multiple slots at one time.

6.The air blow pipe can adjust the position of the air blow port according to the needs, which is convenient for cleaning the slotting waste

7.The conveyor belt can help collect waste and reduce the workload of operators

8.Double-station finished product collection tank, the size can be adjusted according to the product, convenient for operators to collect and sort

SAMPLES: