USAGE:

Under suction grooving machine belongs to the box package production line equipment. The machine is special designed for paper card V type grooving. It suits for box, case or other packaging product, such as phone box, medicine box, watch box etc.

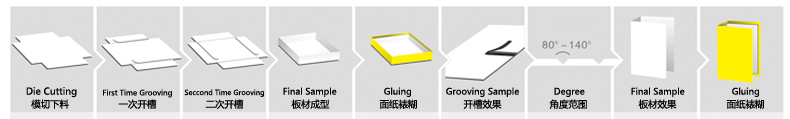

PROCESS:

SPECIFICATION:

Model |

MSKC-W800K |

Min Sheet Size |

80x120mm |

Max Sheet Size |

470x620mm |

Thickness |

220-600gsm |

Knife Angle |

80-140° adjustable |

Feeding Correction Length Of Host 1 |

895mm |

Feeding Correction Length Of Host 2 |

1010mm |

Total Grooving Knives Number |

18 sets, each host with 9 set grooving knives, and 3 row knife holder |

Knife Material |

tungsten steel |

Grooving Speed |

20-100m/min(130-200pcs/min) |

Roll Diameter*Length Of Host 1&2 |

600*800mm |

Power |

6kw |

Voltage |

380v 50hz 3phase |

Precision |

±0.1-0.2 mm |

Net Weight |

3500kgs |

Package Dimension |

2500x1530x1780mm |

|

2050x1400x1570mm |

Gross Weight |

3700kgs |

MACHINE FEATURE:

1. Our cross-shaped grooving machine enables single-pass can achieve horizontal and vertical grooving.

2.The auxiliary blowing system adopts the adjustable delay pause function, which is environmentally friendly and energy-saving.

3.The paper feeding method with downward suction is suitable for 220-600gsm products

MACHINE DETAILS:

1.The paper feeding belt with suction ensures smooth product transportation

2.Adjustable size to suit large and small sizes

3.The paper feeding belt with suction ensures smooth product transportation

4.Adjustable size to suit large and small sizes

5.The part with 3 rows of knives, each row has 3 knives, which can meet the needs of multiple products to open multiple slots at one time.

6.The air blow pipe can adjust the position of the air blow port according to the needs, which is convenient for cleaning the slotting waste

7.The conveyor belt can help collect waste and reduce the workload of operators

8.The belt with suction can ensure the smooth transportation of paper

9.The 1010mm length of deviation correction can ensure the accuracy of the second slotting

10.After the second grooving, the pressing wheels, baffle and conveyor is confirm that the product is output neatly.

11.The output part is located on the right side of the feeder. One person operates one device to achieve high efficiency and save labor costs.

SAMPLES: