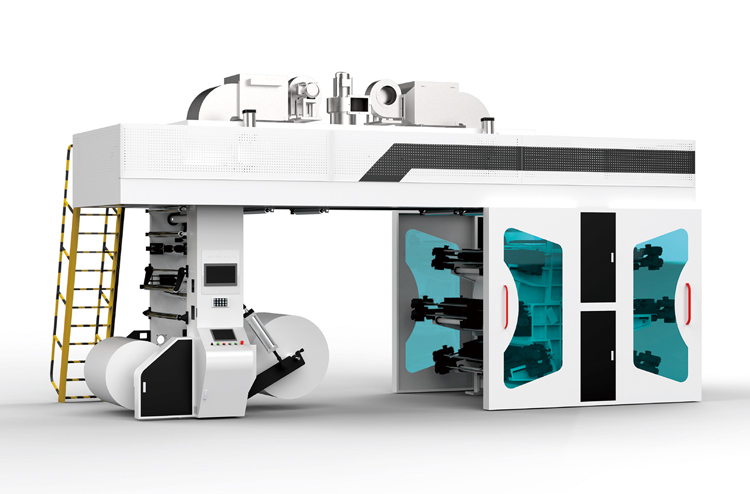

MSCI-B series suitable for roll materials like plastic film, composite film & paper. Ideal for high-speed printing of food, chemical, pharma packaging, shrink film, labels & bags.

SPECIFICATION:

Machine Model |

MSCI-61000 |

Max.Material Width |

1000mm |

Max.Printing Width |

970mm |

Suitable For Material |

plastic film |

Colours |

6 Colours |

Printing Length |

300-860mm |

Machine Speed |

280m/min |

Printing Speed |

250m/min(The speed varies according to different materials.) |

Plate Thickness |

1.7mm /1.14mm/2.38mm(If different plate thickness,please note us) |

Tape Thickness |

0.38mm/0.5mm |

Voltage |

3P 380V 50HZ(If you want different power, pls let me know) |

MAIN CONSTITUTE |

|

UNWINDER UNIT |

|

Max. Unwinder Diameter |

1000mm |

Unwinding Station |

Single unwinder |

Unwinde Epc |

Auto EPC system |

Tension Control |

Automatic tension control |

Unwinding Way |

Active unwinding method/ variable frequency motor control |

Feeding Shaft |

Air shaft |

Axis Core Diameter |

76mm |

Material Loading Method. |

Hydraulic automatic material loading. |

TRACTION UNIT |

|

Traction Constitute |

Rubber wheel and steel roller to roller type |

Traction Motor” |

3.7kw |

PRINTING UNIT |

|

Central Durm |

One set |

Anilox Roll |

Ceramic Anilox roll 6 pcs |

Printing Cylinder |

Standrad (less than 300mm ,according to client request,can extra to pay for 300-860mm) |

Chamber Doctor Blade |

6 pcs |

Driving Type |

High precision helical gear driving |

Adjusting Of Register |

Electric motor |

Printing Precision |

+-0.1mm |

Plated-Glued Roller Adjusting |

hydraulic in and out |

Plc+Touch Screen |

1 set |

Camera |

1 set |

HEATING AND DRYING UNIT |

|

Type Of Heating And Drying |

Electrical heating |

ELECTRIC PARTS |

|

Main Motor |

11kw (Asynchronous servo motor) |

Ink Motor |

6 pcs |

Vertiacl Register Motor |

6 pcs |

Horizontal Register Motor |

6 pcs |

REWINDER UNIT |

|

Max. Rewinder Diameter |

1200mm |

Rewinding Station |

Single Rewinder |

Rewinder Type |

Central rewinding/ variable frequency motor control |

The Receiving Shaft |

Air shaft |

Axis Core Diameter |

¢76mm |

Unloading Methods |

Hydraulic automatic blanking |

MACHINE FEATURE:

1.After mounting the plate and registration, no longer need registration, improve yield;

2.Replacing 1 set of Plate Roller (unloaded 6pcs old roller, installed six new rollers after tightening), only 30 minutes registration can be done by printing.

3.The machine's first mount plate, pre-trapping function, is to be completed in advance prepress trapping in the shortest possible time.

4.Maximum production machine speed up 250m/min, registration accuracy ±0.10mm.

5.The overlay accuracy does not change when lifting the running speed up or down.

6.With precision structural, easy operation, easy maintenance, a high degree of automation, and so on, one person can operate.

DETAILS:

1. 100mm thick wall panels, The frame and wall panels are integrally poured, using precision cast iron material, which effectively eliminates the vibration of the whole machine, and is designed for high -level and high- quality prints to ensure the stability of the whole machine’s color register during high-speed operation.

2. The printing stick adopts an enlarged thick steel bar and is plated with a 10 wire thick hard chrome protective layer for polishing. The aluminum alloy guide wheel is subjected to hard oxidation, dynamic balance and static balance treatment.