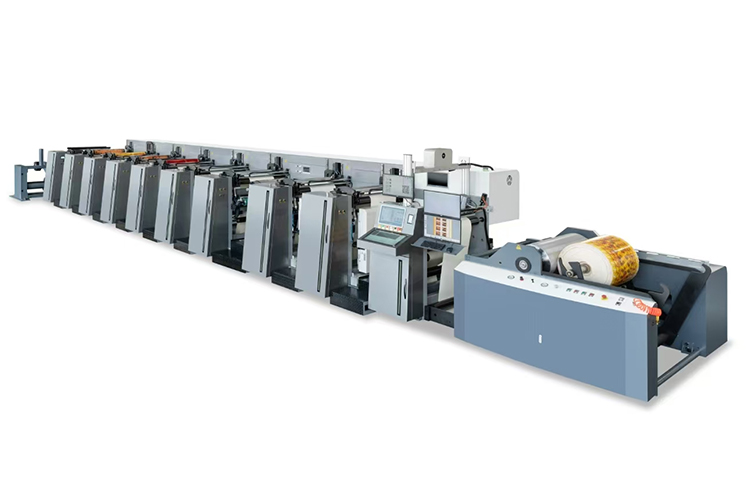

MSTS series flexographic printing press is suitable for printing on 17gsm copy paper, cotton paper, 80-400gsm Art Paper, Aluminum-foil paper, cardboard and kraft paper.

SPECIFICATION:

Specification |

MSRY-TS1020 |

MSRY-TS1220 |

MSRY-TS1350 |

MSRY-TS1450 |

Max.Web Width |

1020mm |

1220mm |

1350mm |

1450mm |

Max.Printing Width |

1000mm |

1200mm |

1320mm |

1430mm |

Printing Repeat Length |

350-1100mm |

|||

Max.Unwinder Diameter |

1524mm |

|||

Max.Rewinder Diameter |

1524mm |

|||

Gearing |

Printing plate without tooth pitch requirements |

|||

Machine Speed |

300m/min (max. mechanical speed ) 150 ~ 220m/min ( max. printing speed ) (depends on different product plate designs ) |

|||

Plate Thickness |

1.7mm |

|||

Double Sides Adhesive Tape |

0.38mm |

|||

Diameter Of Web Roller |

100mm |

|||

Drying Mode |

Hot Air Drying + IR Drying + UV Drying |

|||

Ink Used |

Water based Ink & UV Ink |

|||

Power Requirement |

380V 3PH 50Hz |

|||

Printing Material |

30~350gsm |

|||

MACHINE FEATURE:

1.Sleeve type printing plate roller, convenient and fast plate changing, orders of varying sizes are not restricted;

2.Petal-type structure, stable printing pressure, high-speed work stability;

3.Full servo driven, printing repeat length no limited of teeth pitch, high adaptability;

4.Water-based ink and UV inks are universal, can choose ink types according to the requirements of the printing product, or mix it to adapt to a wider range of printing patterns and printing materials;

5.Digital full inspection and brush code to the plate with preregistration, reduces machine dependence on people with higher yield.

DETAILS:

UNWINDING UNIT

1. Shaftless unwinding unit

2. Unwind unit 60”(1524mm)capacity

3. Mandrel 3” and 6” diameter

4. Hydraulic paper shaft lifting and descending device: mainly used for loading and unloading of paper rollers, no need of forklift or other handling tools

5. Web break sensor, automatically shut down when paper broken

TRACTION PAPER INFEED SYSTEM & WEB GUIDE SYSTEM

1. Paper Splicing Table: with pneumatic paper holding device.

2. Ball screw electric actuator

3. Adopt the photoelectric sensor for web guide transmission

4. Electronic web guide traction device. If there is any excursion in paper feeding,the system will have a constant and accurate adjustment

5. Adopt closed loop control system to accurately detect the deviation and correct it

6. Hard Anodization to the paper guide HV 800-1000

7. Inspection:the edge

8. Web Guide precision:±0.02mm

9. The front tension unit adopts an integral alloy cast iron wall panel

10. Independent servo motor drive, combined with a constant tension control system, ensures stable tension

PRINTING UNIT (Double Servos, Shaftless transmission Petal type Sleeve Cylinder Structure)

1. The frame is integrally cast with alloy cast iron material, effectively eliminating overall vibration and making the machine more stable and durable

2. 12 servo motors ( 5 color ) independently drive the pressure roller and cylinder roller

3. The sleeve version drum is driven by an independent servo motor

4. The unique support structure of the printing plate cylinder allows for the replacement of the printing plate without adjusting the pressure

5. 5 printing plate rollers (the size of the roller is determined by the customer, and the printing repeat length is within 450mm)

6. 5 high-precision ceramic anilox rollers (anilox roller LPI is determined by the customer)

7. CCD Intelligent color registration system with pre registration function configured

8. 6 sets of ink scraping systems, no tools required, can be directly inserted

9. 6 ink transfer rollers on the ink path to ensure the ink loading capacity of the anilox roller during high-speed operation

10. Pneumatic clutch pressure for mesh roller and plate roller, fixed position for mesh roller

11. Quick replacement of plate rollers and stainless steel ink cartridges without the need for any tools

12. Automatic cleaning of the printing plate function: After each shutdown, the mesh roller is released from the pressure, and the plate roller continues to rotate for 1.5 seconds to transfer the ink on the printing plate to the paper, keeping the printing plate clean.

13. Web roller rotation function: Each time the machine is stopped, the web roller will automatically operate to prevent ink from drying and solidifying on the surface of the web roller, causing mesh hole blockage.

14. The high-precision micro adjustment device of the mesh roller ensures the pressure between the ceramic mesh roller and the plate roller

15. Full runout of mesh roller, plate roller, and bottom roller: ≤ 0.03mm

DRYING UNITS- HOT AIR DRYING +IR DRYING +UV DRYING

1. Infrared (IR) shortwave heating and drying system, with adjustable temperature and independent switch control

2. Combination of hot air and natural cold air blowing (including extraction and blowing fans), with adjustable intake and exhaust air volumes for each group

3. The air duct is made of Korean Teflon material

4. Each printing group is equipped with a separate hot air blower to ensure drying quality (5 blowers, 1 suction)

5. Configure a circulating return air system to reduce energy consumption

VIDEO WEB FULL INSPECTION SYSTEM

1. Real time image capture and detection of printed materials during the printing process, with automatic left and right lateral movement

2. Can Automatically set horizontal and vertical detection position

3. Able to magnify and observe the detection image, ensuring printing quality

4. Install support devices and electrical connection interfaces

5. High definition camera

6. One high-definition color image monitor

7. One high-speed capture strobe light

TRACTION PAPER OUTFEED SYSTEM

1. The rear tension unit adopts an integral alloy cast iron double wall panel

2. Independent servo motor drive, combined with a constant tension control system, ensures stable tension

3. One servo motor

4. One servo driver

REWINDING UNIT

1. Single station unwinding unit 1 set

2. 3 inch inflatable shaft 1 set

3. Unwind unit 60”(1524mm)capacity

AUTOMATIC LUBRICATING SYSTEM

1. The gear’s automatic dampening system can adjust the lubricating time and ration

2. When the dampening system breaks down or the lubrication is not enough, the indicator will alarm automatically.

PLATE MOUNTER

1. It has a screen including the bilateral symmetrical split screen display

2. It is used for the plate mounting to realize the purpose of multi-color overprinting

3. One set image segmentation device

4. 2 high definition cameras for magnifying

5. Quickly changes the print plates

WEB CLEANER AND ANTI STATIC UNIT

1. To guarantee the cleanness of substrates

2. First remove static, then clean the dust in vacuum and then remove static